Precise Profile Measurement

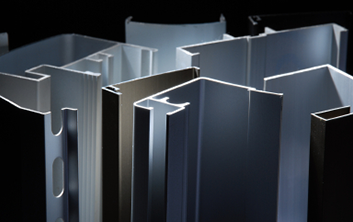

It's specialized for extrusion quality control managers who want to see the big picture, not only partial measurements with calipers and optical comparators.

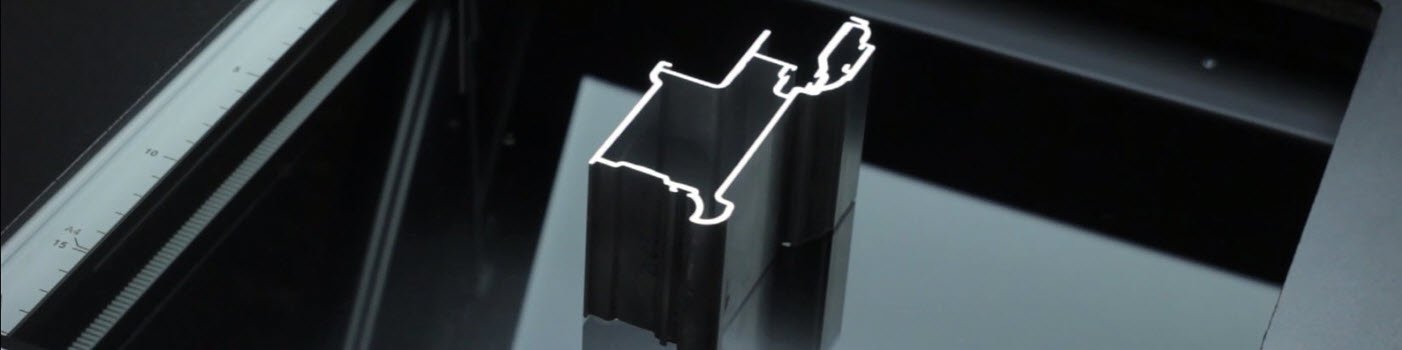

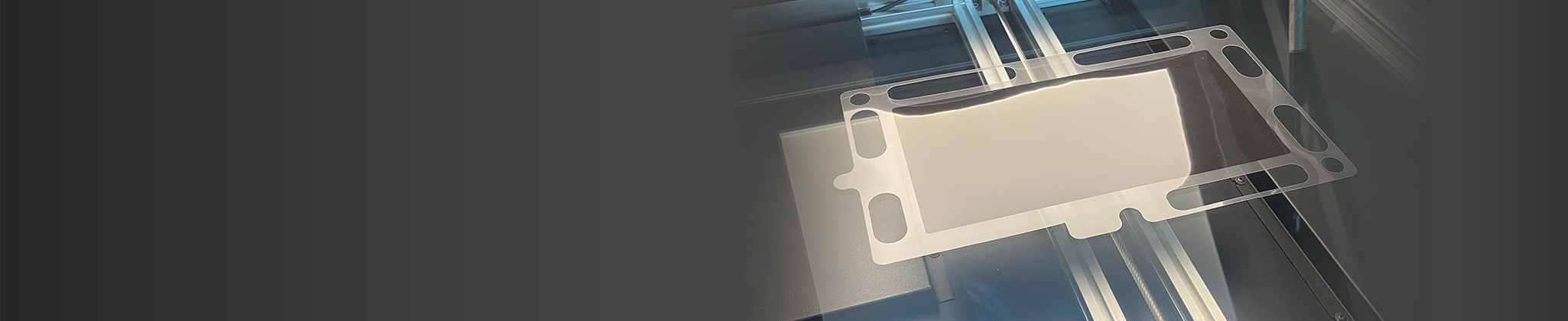

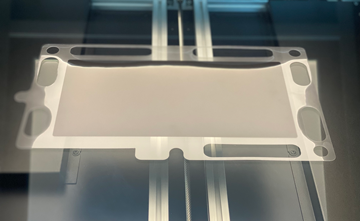

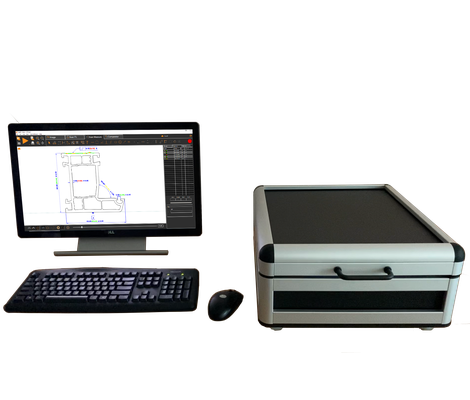

Scan Fit and Measure is a 2D system for automated measurement and inspection of the geometry of extruded profiles. It is used as a quality control tool allowing various types of production facilities to benefit by reducing costs and minimizing product deviations. The flatbed scanner technology is suitable for measurement of profiles from aluminum, plastic, rubber, silicon and medical tube extrusion as well as parts from sheet materials like gaskets and membrane electrode assemblies (MEAs) used for hydrogen fuel cells.

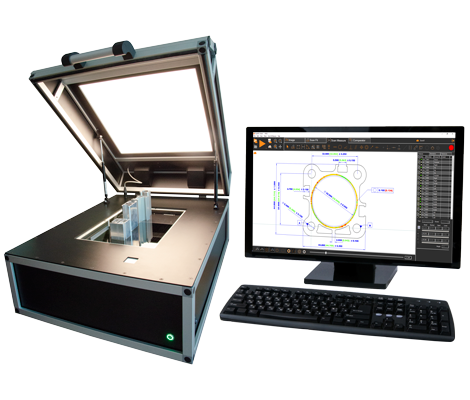

Easy to set up and use, the SFM measurement system delivers instant PASS/FAIL evaluation based on a rich set of customer’s predefined geometric dimensions and tolerances. It provides a visual comparison of the scanned image to the CAD model based on the precise measurement of size, position, wall thickness and GD&T (Geometric Dimensioning and Tolerancing).

Large field of view area of up to 400mm x 600mm (16" x 24") allows sizable and multiple part measurement thus speeding quality control and ensuring an intact and continuous production flow.

SFM 600

Technical Specifications

Maximal Measuring Area

600mm x 400mm (24" x 16")

Average measuring speed (multi-part)

~15sec per part

XY Accuracy

E2 = (30 + 25L/1000)μm

Maximal Part Weight

5 kg (11 lbs)

Operating temperature range

10°C - 35°C (50°F - 95°F)

System Dimensions (WxDxH)

850 x 1250 x 400mm (33" x 50" x 16")

Footprint (WxD)

750 x 770mm (29" x 30")

Maximal Part Height

110mm (4")

SFM 250

Technical Specifications

Maximal Measuring Area

200mm x 250mm (8" x 10")

Average measuring speed (multi-part)

~5sec per part

XY Accuracy

E2 = (20 + 20L/1000)μm

Maximal Part Weight

2 kg (5 lbs)

Operating temperature range

10°C - 35°C (50°F - 95°F)

System Dimensions (WxDxH)

420 x 530 x 230mm (17 " x 21" x 9")

Footprint (WxD)

380 x 420mm (15" x 17")

Maximal Part Height

80mm (3.1/8")

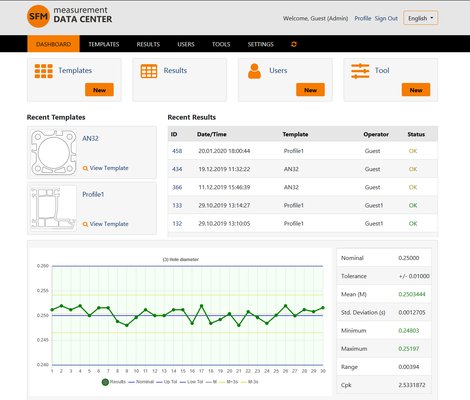

Measurement Data Center

Data Collection Software

ENSURES TRACEABILITY

The Measurement Data Center (MDC) is a data collection software that ensures that each measurement is tracked and stored on a local server or in the cloud. The software adds traceability to the quality control process of any production facility. It is also a collaboration tool that stores templates, measurement routines and measurement results. MDC integrates seamlessly with other measurement software, a guarantee that no measurement result is ever lost.

CONNECTS TO VARIOUS TOOLS

MDC can connect and collect data from the SFM systems and from digital gauges like calipers, micrometers, indicators and other measurement tools.

GENERATES REPORTS

The system provides visual representation of the measurement data, displaying the results in graphics and tables. It can generate a report for a single measurement or over a period of time.

CLOUD OR LOCAL SERVER

The MDC could be accessed online or it could be installed on a local server inside the factory.

System Features

- Multiple parts measured with one scan for speed and reduced workload

- One-time CAD measurement template preparation

- Rugged design for shop floor operation

- Profile, dimensional and comparator's views for unambiguous evaluation

- Open-standard data output for integration with other information and reporting systems

- Open-standard data input for integration with 3rd party measuring devices

- Constructed features for comprehensive measurement

- Profile Tolerance with whiskers and zone visualization

- Rich set of geometric dimensions and tolerances

- Precision comparable to a digital caliper

- 3 day set-up and user training for fast implementation

- Measurement Data Center for statistics, results analyses and report generation (MS Excel, OO Calc, PDF).

- Touchscreen comparator for automatic and manual visual inspection

- Automatic Part recognition (AutoID)

- One button measurement with automatic BestFit part alignment

- Assembly Inspection

Contacts

Offices

Europe

Tsvetelina Nacheva

Office Express IT Center. 5th Floor 135 Tzarigradsko Shosse Blvd., 1784 Sofia, Bulgaria

Phone: +359 2 976 83 12

Fax: VAT: BG201277917

E-mail: info@sfmeasure.com

North America

Kris Hanchette

2201 Long Prairie Rd, Suite 107173, Flower Mound, Dallas, TX 75022

Phone: +1 469 902 9754

E-mail: kris.hanchette@engview.com

South America

Matheus Pires

Metropolitan Square Business R. Luso-Brasileira, 4-44, Sala 1008 Jardim Estoril, Bauru

Phone: +55 11 984 243 884

E-mail: info@sfmeasure.com

Distributors Europe, Middle East and Africa

Karl Lenz

Nassaustraße 11 D-65719 Hofheim-Wallau, Germany

Phone: +49 6122 99 68 0

E-mail: kjl@ogpgmbh.com

Please select a country to find your local distributor from OGP network

France, Morocco, Tunisia, Algeria

OGP France

Israel

Globus Technical Equipment

Italy, Slovenia, Greece

OGP HOMMEL ITALIA Srl

Luxemburg, Belgium, Netherlands

Measuretec

Poland

Oberon3D

Spain

Metrotecnica

Sweden, Norway, Finland, Estonia, Latvia, Lithuania

OGP Skandinavia AB

Switzerland

OGP AG

Turkey

YAMER

United Kingdom

OGP UK

Portugal

Eurotecnologia

Distributors North America

U.S. states of PA, NJ, DE, MD, VA, NY

Mark Conti

407 West Elm Avenue, North Wales, PA 19454, USA

Phone: +1 215 283 0156

E-mail: markc@holcosales.com

Mexico

AccurEasy Metrología Absoluta.

Edgar Luna

Av. Don Bosco 41 Loc. 31, El Pueblito, Corregidora, QRO. 76900. MÉXICO

Phone: +52 1 442 1719699

E-mail: edgar@accureasy.mx

Distributors Asia

QVI India

Shreyansh Hippargi

#55 1st Floor, RS Tower, Hosur Main Road, Bommasandra, Bengaluru – 560099, India

Phone: +91 9689866161

E-mail: shreyansh@qviindia.com

OGP Shanghai

Viki Lv Rong

Building 8, No. 11, Galileo Road, Zhangjiang, Pudong, Shanghai, China

Phone: +86 21 50458383

E-mail: viki_lv@smartscope.net.cn